First Article Software is a crucial tool in manufacturing that streamlines the First Article Inspection (FAI) process. It ensures that the first product produced in a batch meets design and quality standards before mass production, helping manufacturers quickly identify and correct potential issues, which is vital for maintaining product quality and minimizing costs.

“First Article Software streamlines the First Article Inspection (FAI) process in manufacturing, ensuring that initial production units align with design specifications before mass production. It improves quality control and compliance by simplifying documentation.”

In this article, We will discuss “ what is first article software”

Understanding the First Article Inspection (FAI) Process:

FAI is a critical quality control process that verifies the accuracy and quality of the first article produced. It typically involves several key steps:

- Preparation: Before the actual inspection, the inspection team gathers all relevant documentation, including assembly instructions, engineering drawings, and specifications necessary for evaluating the product【46†source】【45†source】.

- Inspection: The first article is meticulously examined using various methods, including dimensional measurements, visual inspections, and functional testing. The goal is to ensure that the part conforms to all required specifications【46†source】.

- Documentation: After inspection, the results are documented in a comprehensive First Article Inspection report. This report summarizes the findings and provides a record of the inspection process, which is vital for both compliance and continuous improvement efforts【45†source】【46†source】.

- Approval or Rejection: Based on the documentation, the inspection team decides whether the first article meets the necessary quality standards. If it does, mass production can commence; if not, corrective actions must be taken before production can continue【46†source】【45†source】.

Key Features of First Article Software:

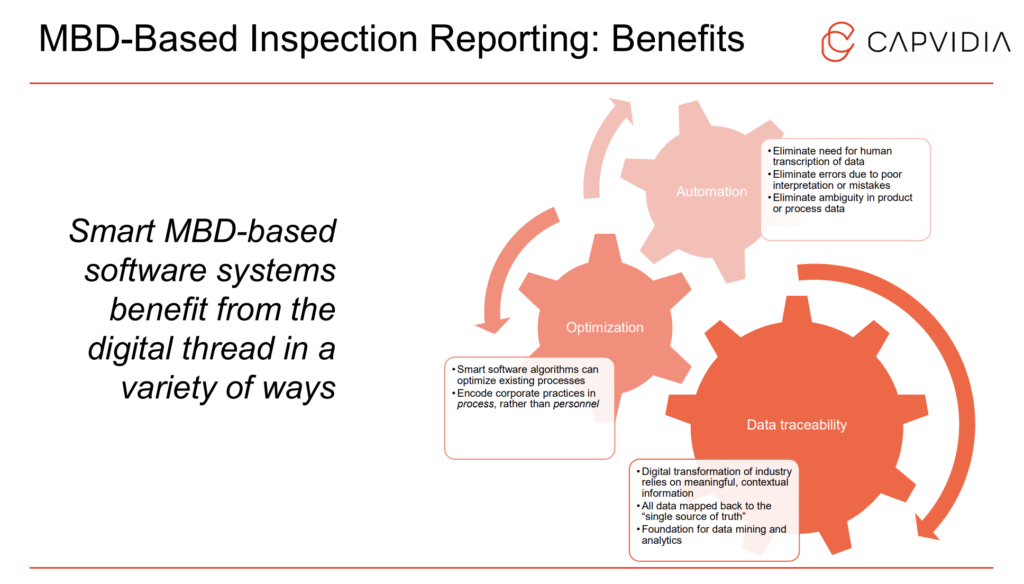

1. Automated Reporting:

First Article Software automates the creation of inspection reports, ensuring documentation consistency and accuracy. This not only helps manufacturers comply with industry standards but also minimizes human error, speeding up the review process【46†source】【45†source】. By providing real-time insights, the software enables manufacturers to address potential issues promptly, further enhancing product quality and operational efficiency【45†source】.

2. Integration with Manufacturing Systems:

Many First Article Software solutions offer integration capabilities with existing manufacturing execution systems (MES), enterprise resource planning (ERP) systems, and other quality management tools. This integration allows for seamless data sharing and enhances overall efficiency【45†source】【46†source】. Furthermore, it facilitates better collaboration among departments, ensuring that all teams have access to accurate and up-to-date information throughout the production process【46†source】.

Also Read: What Is A Good Minor To Pair With Software Engineering – Ideal Minors For Software Engineers!

3. Real-Time Monitoring:

With real-time monitoring capabilities, the software allows manufacturers to track inspection progress and results as they happen, enabling quicker decision-making and response to potential issues【46†source】. This feature not only enhances operational efficiency but also improves the overall quality assurance process by providing immediate feedback on inspection outcomes. By allowing teams to act swiftly on any discrepancies, manufacturers can significantly reduce the risk of defects slipping through the cracks【45†source】.

4. Customizable Workflows:

First Article Software often includes features that allow manufacturers to customize their workflows according to specific needs and processes. This flexibility is crucial for adapting to various manufacturing environments【45†source】【46†source】.First Article Software also typically offers integration with existing systems, enhancing data sharing and collaboration across departments.

5. Data Analytics:

Advanced analytics tools within the software help manufacturers analyze trends in inspection data over time, enabling them to identify recurring issues and improve their manufacturing processes【46†source】.Additionally, these tools can generate detailed reports that assist in compliance with industry standards and regulations. By leveraging real-time insights, manufacturers can make informed decisions to enhance product quality and efficiency.

Benefits of First Article Software:

- Improved Quality Control: By enabling thorough inspections of initial production items, First Article Software significantly enhances quality control efforts. Manufacturers can identify defects early in the process, reducing the risk of costly recalls and ensuring compliance with regulatory standards【46†source】【45†source】.

- Increased Efficiency: Automating the FAI process reduces the time and resources needed for manual inspections, allowing manufacturers to focus more on production and less on administrative tasks【45†source】【46†source】.

- Cost Savings: By catching errors early and ensuring that products meet specifications before mass production, manufacturers can save on costs associated with rework, scrap, and downtime【45†source】【46†source】.

- Enhanced Communication: First Article Software fosters better communication among teams by providing a centralized platform for tracking inspection results and addressing issues promptly【46†source】【45†source】.

Who Uses First Article Software?

First Article Software is widely used across various industries, particularly in sectors where precision and compliance are critical. Industries such as aerospace, automotive, electronics, and medical devices rely heavily on FAI to ensure that their products meet stringent quality standards【46†source】【45†source】. Notable manufacturers in these sectors adopt First Article Software to enhance their quality assurance processes and minimize risks associated with product defects.

FAQ’s

1. What is First Article Software?

First Article Software is a tool designed to streamline the First Article Inspection (FAI) process in manufacturing, ensuring that the initial production items meet design specifications and quality standards before mass production begins【45†source】【46†source】.

2. Why is First Article Inspection important?

First Article Inspection is crucial for identifying defects early in the production process, which helps reduce costs associated with rework, ensures compliance with industry standards, and enhances overall product quality【45†source】【46†source】.

3. Who typically uses First Article Software?

This software is primarily used by manufacturers in sectors such as aerospace, automotive, electronics, and medical devices, where precision and regulatory compliance are essential【45†source】【46†source】.

4. What are the key features of First Article Software?

Key features include automated reporting, real-time monitoring, data analytics, customizable workflows, and integration with existing manufacturing systems to enhance efficiency and quality control【45†source】【46†source】.

5. How does First Article Software improve quality control?

By automating the inspection process and providing detailed documentation, First Article Software allows manufacturers to catch and address potential issues early, ensuring that products meet required specifications and enhancing overall quality【45†source】【46†source】.

Conclusion

In conclusion, First Article Software is a crucial tool for manufacturers, facilitating the First Article Inspection (FAI) process to ensure initial production items meet quality and design standards. By automating inspections and documentation, it enhances quality control, reduces costs associated with defects, and supports regulatory compliance. This software is essential for industries where precision and quality are paramount, helping manufacturers maintain high production standards【45†source】【46†source】.