3D printing software is essential for creating, slicing, and optimizing digital models into physical objects, with various tools available to suit different user needs and printer types.

This article explores what 3D printing software is, its types, key features, and how to choose the best software for your needs.

What is 3D Printing Software:

3D printing software refers to a set of tools that allow you to design, prepare, and print 3D models. It takes a digital design (typically from CAD software) and converts it into machine-readable G-code, providing instructions for the 3D printer to follow. Essentially, it bridges the gap between the digital and physical world.

Types of 3D Printing Software:

3D printing software is generally categorized based on its primary function. Each type is designed to perform specific tasks in the 3D printing process, from creating models to slicing them for printing.

Also Read: OBS Studio Download – The Complete Resource!

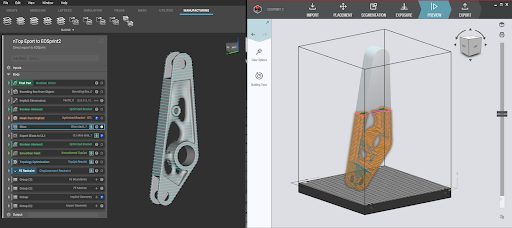

CAD Software for 3D Printing:

CAD (Computer-Aided Design) software is used to create digital 3D models. These tools are essential for designing precise, editable models for 3D printing. CAD software is used for both simple and complex designs, offering a wide range of features. Popular CAD tools include AutoCAD, SolidWorks, and TinkerCAD, each offering different strengths depending on the complexity of your design needs.

Slicing Software:

Slicing software is crucial for converting 3D models into printable instructions. It takes a 3D model and divides it into horizontal layers before generating G-code instructions for the 3D printer. Good slicing software optimizes print settings, such as layer height, print speed, and material use, ensuring the best possible results. Popular slicing tools include Cura, PrusaSlicer, and Simplify3D, each known for its ease of use and customization options.

3D Printer Management Software:

For users managing multiple 3D printers, printer management software allows you to monitor, control, and optimize the printing process across several machines. This software is helpful for streamlining large-scale printing operations, tracking print progress, and managing print queues. Tools like OctoPrint and MatterControl offer remote monitoring and control features, which are essential for organizations or individuals running several printers at once.

3D Modeling Software for 3D Printing:

3D modeling software enables users to create and modify digital 3D models that can later be 3D printed. These programs offer powerful design tools for shaping and sculpting objects with a high level of detail. Popular modeling software includes Blender, SketchUp, and Rhino, each offering unique capabilities for creating complex or simple 3D objects. These tools are essential for designers and hobbyists looking to bring their ideas to life.

Mesh Repair and Optimization Software:

Mesh repair software is used to fix any issues with a 3D model that could prevent successful printing. These issues can include holes, inverted normals, or non-manifold geometry that may lead to errors during the printing process. Mesh repair tools help ensure that the model is “print-ready” by repairing these errors and optimizing the model for printing. Meshmixer and Netfabb are two of the most popular mesh repair tools in the 3D printing community.

Key Features to Look for in 3D Printing Software:

When selecting 3D printing software, consider the features that best suit your project. Some features will help you optimize prints, while others will make your design workflow more efficient.

Ease of Use:

If you’re a beginner, it’s essential to choose software that has a simple, user-friendly interface. Software should make it easy to import models, slice them, and start printing with minimal steps. The learning curve should be manageable, and the most common tasks should be easily accessible.

Compatibility:

Before selecting 3D printing software, ensure that it is compatible with your 3D printer. Some software only supports specific printer models or brands, so check the list of supported printers to avoid compatibility issues. Many slicers, like Cura and PrusaSlicer, support a wide range of printer brands and models.

Advanced Control:

Experienced users may require more advanced control over print settings. Features like customizable layer height, print speed, and infill density allow users to fine-tune the printing process for optimal results. Look for software that provides detailed control over these settings, enabling you to adjust the print process based on specific needs.

Slicing Options:

Powerful slicing software offers a variety of options to adjust print quality, material efficiency, and speed. Look for software that allows you to control important slicing parameters such as support structures, infill patterns, and the number of shells. These options give you flexibility in how you print your designs, whether you prioritize speed, quality, or material use.

Cloud Integration:

Cloud-based 3D printing software offers the ability to access and manage your designs remotely. This feature is beneficial for collaborative projects and managing multiple printers. Cloud integration allows users to share designs, monitor print progress, and access software tools from any device, providing greater flexibility for managing 3D print farms or working as part of a team.

How to Choose the Best 3D Printing Software:

Choosing the best 3D printing software depends on your experience level, the complexity of your projects, and the type of printer you’re using. Beginners should prioritize software that is simple and intuitive to use, while more advanced users may look for software with extensive customization options. Always ensure the software supports your specific printer model, and consider additional features such as cloud support, slicing flexibility, and print management tools.

FAQ’s

1. What is the role of slicing software in 3D printing?

Slicing software divides 3D models into thin layers and generates print instructions for the 3D printer. It determines key settings such as layer height, print speed, and infill density to ensure a successful print.

2. What software do professionals use for 3D printing?

Professionals typically use advanced CAD tools like SolidWorks and Fusion 360 for modeling, paired with slicing software like Simplify3D or PrusaSlicer for optimizing print settings.

3. Can you 3D print directly from CAD software?

Most CAD programs don’t allow direct printing, as they don’t generate the G-code necessary for printing. Typically, slicing software is required to prepare the model for printing.

4. How can I repair a damaged 3D model?

Mesh repair software like Meshmixer or Netfabb can automatically detect and fix issues such as holes, self-intersections, or inverted normals in 3D models.

5. Is there free 3D printing software available?

Yes, there are several free 3D printing software options, including TinkerCAD (for beginners), Cura (for slicing), and Meshmixer (for mesh repair), which provide basic to advanced features.

Conclusion

3D printing software is essential for transforming digital designs into physical objects. By selecting the right tools, from CAD to slicing to print management, you can enhance your 3D printing process and achieve better results. Choosing the best software for your needs will optimize your workflow and ensure high-quality prints every time.

Related Posts

Also Read: Free CAD Software – An In-Depth Overview!

Also Read: Best Video Editing Software – A Comprehensive Guide for 2024!

Also Read: Live Chat Software – A Guide to Improving Customer Support!